Tensotherm with Nanogel: for Light, Insulated Tensile Roof Structures

No really – it isn’t like learning about the War of Jenkins Ear, where you have to imagine being alive in the 1700’s and fighting with a large group of Spanish and British soldiers and it’s a bit of a stretch. You know what compression when you attempt to balance a pile of textbooks about colonial military campaigns on your head and your neck shortens, and you understand tension because you actually feel it when you pull on a locked doorknob.

Image courtesy wikimedia commons

So far I haven’t worked on any projects like the Denver Airport, where tension and its expression are major elements of the design. But I am working on a competition entry that will incorporate wind-resistant architectural fabric, and research for that project caused me to dig through my lovely ARCHITERIALS submissions inbox where I found product information from Tensotherm™ with Nanogel®, developed by Birdair, Cabot Corporation and Geiger Engineers.

Tensotherm is a tensile fabric material that insulates like standard roofing, although it can be made translucent if you’re interested in letting light shine in. According to the product literature, “Tensotherm is comprised of two layers of PTFE fabric membrane with a layer of Nanogel aerogel sandwiched between the two layers. PTFE, or polytetrafluoroethylene, is a Teflon®-coated woven fiberglass membrane that is extremely durable and water resistant; it is capable of withstanding temperatures from -100°F to +450°F, immune to UV rays, and waterproof.” The aerogel layer is as light as a feather and as an insulator it makes whale blubber look pathetic (please do read this post for more on the awesome characteristics of aerogels).

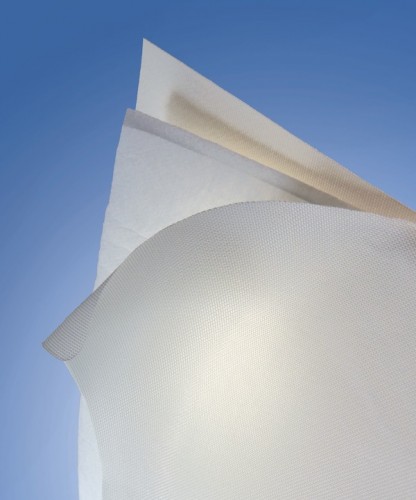

Image courtesy birdair.com

The product is manufactured in Tijuana, Mexico, but unlike strong narcotics arriving daily from South and Central America, Tensotherm is suitable for use as roofing in stadiums, arenas, schools, convention centers, transportation facilities, retail facilities and more. Don’t use it for open-air structures, as it’s not suited for the application.

Image courtesy birdair.com

While it’s hard to know what goes in to the manufacturing process, translucent Tensotherm could contribute to a green building strategy that incorporates daylighting, and if it’s indeed an effective insulator it could reduce heating and cooling loads in buildings. Another benefit of a lightweight, tensile roof is the fact that support structure can be smaller in size; this reduces expenditures on shipping and installation. The system produces very little job site waste and the fabric can contribute to the acoustic environment.

Have you used Tensotherm or similar products in your work? Let us know what’s what in the comments!

I have filed Tensotherm under Wood because it’s great in tension.

Leave a Wordpress Comment: