CalStar Fly Ash Brick “Comes in Eight Colors. All of them Green.”

When I first heard the term “fly ash” in architecture school, I remember thinking that it sounded pretty sick. I mean, flies are annoying and it’s gross when they buzz over and land first on some unidentified, dog-generated substance on the ground and then, without a single shred of consideration, approach and settle on the rim of your drinking cup or slice of pecan pie. But it boggles the mind to think about the enormous number of flies you’d have to crisp in order to produce so many metric tons of fly ash that there’d even be a need to recycle it!

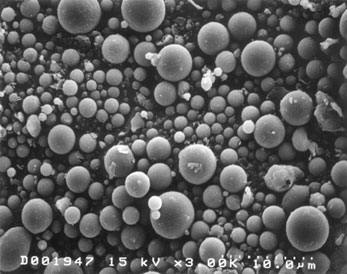

My horror abated only slightly when I realized that fly ash is not, as I’d assumed, the cremated remains of über-obnoxious insect life, but rather a residue generated during the process of combustion. Fly ash is so named because of the fine particles that rise (or fly) up into the atmosphere with flue gases when factories burn substances like coal (so thanks for setting me straight, Wikipedia). The stuff is toxic and nasty, and will say mean things about your mother.

Image courtesy wikimedia commons

Fly ash can be collected before it skips up into the sky, over the hills and into our lungs, and it can be used to manufacture building materials such as concrete masonry units or bricks. To that end, CalStar Products, Inc. opened a green brick and paver plant in order to manufacture bricks out of fly ash in Caledonia, Wisconsin back in January, 2010. Why Caledonia? I do not know, but I assume it is a lovely town.

The embodied energy (the amount of energy that goes into extracting and processing raw materials, transportation costs, manufacturing, etc) of a common clay fired brick is listed in the National Institute of Standards and Technology (NIST) Building for Environmental and Economic Sustainability (BEES) database at 8800 British Thermal Units. According to CalStar’s product literature, “producing fly ash brick consumes less energy and emits less CO2 because it does not require firing to harden the masonry units nor is any cement used as a binder. The CalStar green brick solution represents 85% lower embodied energy and 85% lower CO2 than fired clay brick” (CalStar). Some forms of fly ash contain a high concentration of calcium oxide (lime) which might be what is allowing the CalStar bricks to “self-cement” without firing, although that is conjecture on my part.

Image courtesy CalStar

CalStar claims that their commercial Fly Ash Brick (FAB) “meets or exceeds the same standards of equivalent masonry products, is available in modular and utility sizes, and comes in eight colors. CalStar’s products are designed to be price competitive with traditional products of equivalent quality.” I’d be interested to know if anyone has used these bricks in a project yet, and if they’re performing any differently from traditional bricks. Hit the comment section with your thoughts!

Fly Ash bricks are being filed under “earth” because that’s where I file bricks. I considered including them in the wood category but decided against it.

Cited:

“CalStar Products, Inc.” Sweets Network. Accessed 10/12/10. URL.

Calstar Products Website. Accessed 10/12/10. URL.

This is what I don’t get. They use a throw away material that needs no firing and no cement, but they still need to qualify that it’s price competitive. How the hell is it not cheaper?

Leave a Wordpress Comment: