Chemically-activated Microtools: Grab Something Tiny!

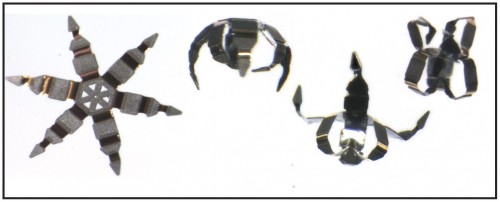

Video snapshots of microgrippers with bidirectional digits closing and opening because of surface chemical modification. (Credit: Jatinder Randhawa, Gracias Laboratory, JHU.)

Microscale engineers at Johns Hopkins are working to develop inexpensive, mass-fabricated microtools that can be deployed in places that aren’t easy to reach (like inside a cow’s bladder, for instance). The thing that makes these v. tiny tools extra awesome is the fact that they are activated by exposure to chemicals rather than by electricity, which means troublesome wires are no longer needed. Also cool is the fact that, “chemical-based actuation of mechanical structures … is widely observed in biological actuators and enables autonomous functioning with high selectivity and specificity” (Gracias).* Microtools that do their job (gripping, cutting, clamping, pick-and-place etc.) in the presence of specific chemicals could find widespread application in the world of materials science.

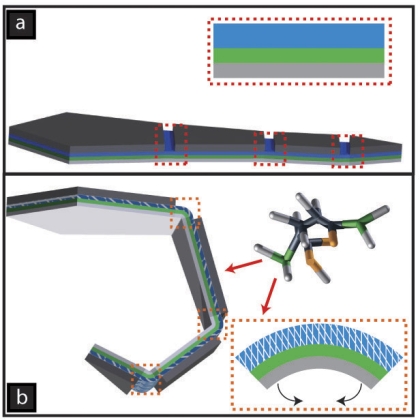

Concept showing a biosensing-microtool component composed of rigid functional elements and hinges (a) as fabricated and (b) on exposure to L-glutamine. This causes the hinges to bend, thereby leading to a concerted motion. (Credit: Aasiyeh Zarafshar, Gracias Laboratory, Johns Hopkins University: JHU).

The researchers are currently “developing biosensing hinges that bend only when they are exposed to specific biochemicals. They can be interconnected with other structural or functional modules using conventional lithographic processes to construct tools (such as grippers) that close or open when exposed to biochemicals” (Gracias). Using surface modifications based on oxidation and reduction of copper films, the researchers managed to achieve reversible actuation of the hinges (meaning that they can open and close over and over again).

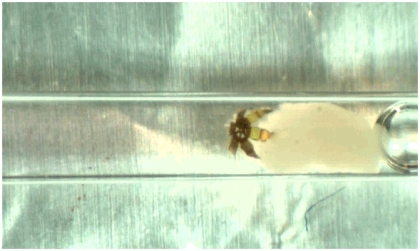

The microgripper hinges are created by stacking multiple layers of thin films (some of which are pre-stressed). One or more of the films undergoes a mechanical transformation upon exposure to a chemical such as L-glutamine or acetic acid. The hinge “functions like a chemical sensor and it responds by bending” (Gracias). The researchers didn’t stop there: they added ferromagnetic elements to the microgrippers so that they could be moved around using magnets, and they also used the tetherless tools to excise cells from a bovine bladder in a test tube. The microgrippers were as small as 700?m when open and 190?m when closed (Gracias).

Video snapshot of a tetherless, biochemically actuated microgripper used to excise cells from a sample. (Credit: Timothy Leong, Gracias Laboratory, JHU.)

But it’s not all rose petals and delicate tears of joy running in lazy, meandering patterns down the faces of scientists. It’s shockingly difficult to engineer the integration of “heterogeneous materials such as metals, polymers, and gels to structure these miniaturized tools using mass-producible lithographic processes… Improvements in sensitivity and selectivity are needed to mimic the capabilities of commercial chemical sensors. Reversible biochemical actuation over multiple cycles is challenging under physiologically relevant conditions and at room temperature” (Gracias). It’s also tough to open and close the microgrippers on demand; it can take hours for certain mechanical actions to take place.

Despite the challenges, the microtools are pretty exciting. I am imagining tiny swarms moving across the surface of a building searching for and reparing microscopic tears or cracks…

I’m filing the microtools under metal because they bend, but I could see putting them in other categories too based on the way they move and the fact that they incorporate polymers etc. I didn’t do that, though.

Cited:

Gracias, David. “Biosensing Microtools” Spie.org 09/15/10. Accessed 09/28/10. URL.

*I loved citing David Gracias in this article, because I felt like I was ending those sentences with a parenthetical “thank you.”

Leave a Wordpress Comment: