Smile: Plastics from Recycled Bottles, Boots, and Banknotes

Image courtesy www.geekinspired.com

Feet grow, but shoes don’t. What this means, of course, is that children go through an enormous quantity of plastic rain boots as their feet get larger. And when they’re done with them and there aren’t any smaller-footed children around, the rain boots get tossed out to molder in landfills.

Smile Plastics gathers up plastic from rain boots, recycled bottles, CD cases, and other polymer-based garbage before it hits the landfill, and recycles it into thin sheets that can be used as furniture, shop fittings, work surfaces, bath panels, screens, and so on.

Some of the plastic material is waste matter generated during industrial production: “faulty products or offcuts or even cutting swarf, and is normally referred to as industrial waste or scrap” (Source: Smile Plastics). Also collected are “post-use” items such as pallet wrapping, drums, sacks, and other packaging. Smile purchases sorted, cleaned plastic that has been granulated into a flake or lump for easy processing.

Smile takes measured amounts of plastic flakes and places them into molds to form six plastic sheets at a time. The molds go into a hydraulic press, where they’re subjected to temperatures up to 180°C and pressures up to 1000 tons. The heat and pressure causes the flakes to fuse together and assume the shape of the mold. According to Smile, their sheets are made from 100% waste plastic without any binding agents or resin.

Image Credit: http://www.smile-plastics.co.uk

Smile conducted an “energy audit” on their operations, to ensure that the recycling process they’re using is worthwhile. They’ve “established that making sheets this way from waste materials uses between 50% and 70% of the energy that would be used to create sheets from virgin material…. Because [they] do not melt the plastic completely, it gives off no noxious or harmful fumes whilst it is being pressed. The only smell is the smell of the perfume used in fabric conditioners as this seems to leach into the plastic bottles in their first life” (Source: Smile Plastics).

The different plastics that go into the press produce wildly varied effects. All of the following images are courtesy Smile Plastics:

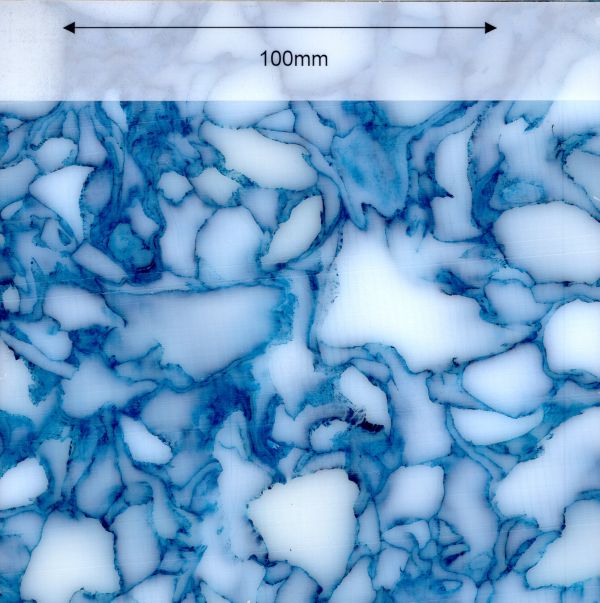

WELLIES are sheets made from the aforementioned recycled children’s rain boots:

BEN sheets are made from suspended shredded Bank of England notes in a clear plastic that was originally reject car headlamp lenses or corrugated conservatory roofs. The density of the notes can be varied.

DAPPLE sheets are made from crushed CDs & plastic water bottles.

CHARCOAL sheets are exceptionally rigid, and they are made from vending machine coffee cups, yogurt pots and refrigerator linings.

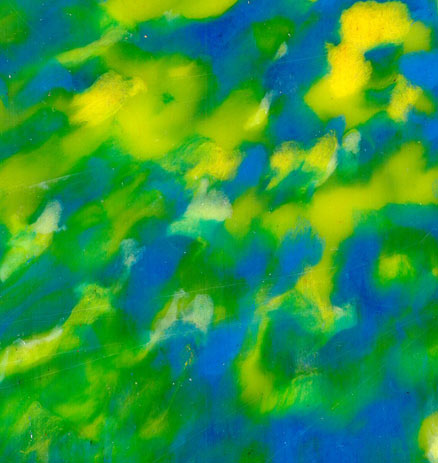

JAZZ sheets are based on underground pipe material. The blue color comes from water pipes and the yellow from gas mains. Jazz is great for use outside.

WU XING:

Plastic is a wood element – it’s flexible and durable.

Cited:

Materia. “Recycled Plastic Sheets.” Accessed 06/21/10. URL.

“How We Make It.” Smile Plastics. Accessed 06/21/10. URL.

Awesome! I love this! I’m an Industrial Design student and I’m definitely going to use their stuff if I can!

Leave a Wordpress Comment: