Absolutely TEX-FAB(ulous)

TEX-FAB bills itself as a “new resource for designers, academics, fabricators, and students seeking out the innovative application of digital technology to the physical environment.” The conference took place from February 4-6th, and consisted of a series of workshops, lectures, and exhibitions. These were meant to engender a network of companies, institutions, and individuals who have a marked tendency to explore parametric design and the digital production of building components (Source: TEX-FAB). I was unable to participate in the entire conference so I’m not sure if said network was engendered. If you were there, please post a comment about it! As for me, I’m going to write about the lectures, workshops, and exhibitions in a slightly under-informed manner.

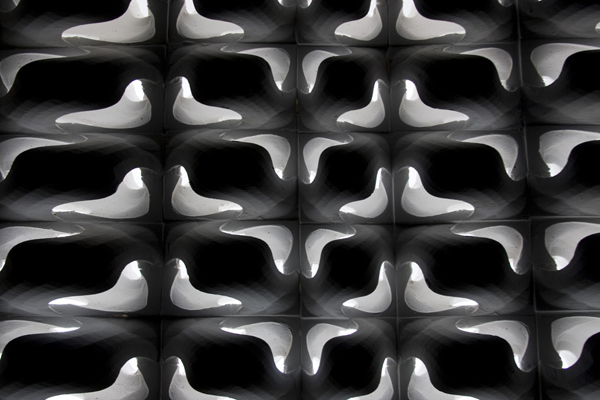

Image credit Nick Richardson, UTA School of Architecture

But first, here’s how I understand parametric design** (you can safely skip this <p> if you wish). First, set up or recognize a design problem – for example, “I need to build a wall in my 400 sf studio apartment because I’m tired of sleeping in the dining room.” Then, set up a bunch of parameters – “the wall has to go from the floor to the ceiling, but it has to be 40% open because otherwise it will make my apartment too dark. It has to be lightweight because the floor can only take x pounds more load. Also, it has to look AWESOME.” (Awesomelookingness is an often unstated yet utterly crucial requirement of all digital fabrication and parametric design). Set up all the parameters in a program or script, then run in it in a 3D modeling software program. You can run the script as many times as you want, tweaking different options and making aesthetic judgements about the results. The output that you like the best, aka your design, can be sent digitally to the people and/or machines who will cut out the parts for your wall. Once these are assembled in your apartment, document the wall for your portfolio and you’re done until it’s time to rennovate again.

LECTURE: SCOTT MARBLE

Marble Fairbanks / Columbia GSAPP, NYC

DESIGNING PARAMETERS / DESIGNING ASSEMBLIES

Thursday 02/04/09, 7:30PM DALLAS ARCHITECTURE FORUM

Image courtesy Marble Fairbanks

This was actually the second time I’d seen Scott Marble give a talk – I think he came to UVa (@UVaSARC) back when I was in graduate school because I recognized the projects he presented from that previous lecture: the slide library for the Art History department at Columbia, the Glen Oaks Branch of the public library in Queens, among others. When I first saw the library it was in design development, and now Marble Fairbanks has built a coordinated Revit (parametric) model of the entire building. Marble reported that the team found a few conflicts between the structural and mechanical systems (by the way, I think Missy Eliott should rap about “miss-coordination” sometime) because they were working in 3D. Marble said, “technology does cost more. You can economize but it’s not going to cut budgets by 20 percent!” He also pointed out that a more coordinated building design might allow for a reduction in the contingency on a project, and that would save money. I guess we’re all wrestling with exactly how best to connect digital designers with fabricators and constructors, and with how offices should be set up and information should flow … and the transition is messy and uncomfortable.

Image courtesy Marble Fairbanks

WORKSHOPS: 5th – 6th, February 2010

I was unable to attend the workshops for two reasons: 1) by the time I found out about TEX-FAB, the workshops I wanted to attend were full; 2) the workshops that were not full cost $90! They sounded amazing however: Paneling Tools with Rajaa Issa, Rhinoscripting with Marc Fornes, and Grasshopper with Andrew Payne. These v. smart people use Rhino 3D modeling software, and they know how to program the software using VBAscript and other methods it to make it do what they want.

EXHIBITION – Partial Architectures

UNIVERSITY OF TEXAS ARLINGTON SCHOOL OF ARCHITECTURE

OPENING: Friday, 02/05/10

Image credit Nick Richardson, UTA School of Architecture

You can go to Arlington to see the exhibition of several digital fabrication projects from around Texas live and in person, or you can visit the TEX-FAB blog and see them digitally. I’d just like to take a moment to include the description of the exhibition in long-quote:

“While the capacity to move across various 2D and 3D digital design platforms suggests a new type of agility for architects and designers, this capability is still largely in an early state of gestation. To some extent the role of these emerging methodologies are most profoundly explored at scales and in modalities not directly confronted by full architectural programs or design requirements. Rather, the partial or the abbreviated become micro-excursions into the possibilities of what these tools and technologies might foreshadow. The incomplete, in this regard, provides a critical stage in developing the evolution of digital design. By focusing on more detailed scales of development and fabrication it is possible to test the physicality of this type of architecture in more rigorous terms. To some extent, the process leading to authoring certain qualitative effects becomes the most tangible result of the partial architecture. Themes of light, surface, materiality, and tactility are all fleshed out to produce a haptic digital architecture.” (Source: TEX-FAB).

So that’s all she wrote for now – I’m going to take a micro-excursion into the possibilities of lunch.

Image courtesy UT Arlington

*A young architect’s means of attaining “street cred.”

**Have I oversimplified this? How would you explain it?

WU XING:

I like to place digifab into the fire category. It often involves lasers, electrons, things catching on fire, etc. so it just feels right. TEX-FAB is also going in metal because it’s been used in a lot of the featured projects in their exhibition.

Doesn’t the difficulty of implementation come from the fact that most buildings are built by a combination of skilled and semi-skilled laborers with a handful of craftsmen? I was reading a short summary of LEAN production and it strikes me that the construction industry, of which we architects are just a small part, has to be one of, if not the most, segmented industries. LEAN concepts can’t be implemented when everybody is chief of their own little canoe. Likewise, I suspect these fabrication methods will meet with a great deal of resistance in the field until someone really starts thinking through a fully integrated delivery system for buildings.

Leave a Wordpress Comment: