Biopolymers – PLA

Image courtesy EcoPaparazzi

Image courtesy EcoPaparazzi

“Polymer” is the generic term for materials formed from large quantities of long chains of molecules called monomers. The properties of any particular polymer are determined by the length and unique molecular structure of the chains. Biopolymers consist of substances derived from renewable resources such as plants, animals, or bacteria: starches from potatoes, corn, tapioca, wheat or maize, cellulose from vegetable cell walls, or proteins such as silk, spider’s webs, or hair (Schmidt). They are composed of as few components as possible, so that biopolymers degrade more easily and are simpler to recycle than traditional petroleum-based synthetic plastics such as polyethylene, polypropylene and polyester. For an in-depth discussion of the properties of plastic especially as they relate to architecture, check out Architecture and Plastic.

PLA Pellets, Image Courtesy earthcycleblog.com

PLA Pellets, Image Courtesy earthcycleblog.com

PLA (polylactic acid) is one of the most important biodegradable plastics around today. Lactic acid is the base material for this biopolymer, which is especially valued for short-dated packaging (films and foils) but it can also be used for long-life products depending on its composition (Schmidt). From now on when I’m sore from working out I’m going to think about PLA. Is that weird?

Pressed PLA Granules. Image courtesy architonic.com

Pressed PLA Granules. Image courtesy architonic.com

PLA and other biopolymers are seeing upticks in demand due to economies inherent in increased production capacity and widespread interest in degradable plastics. I’ve come across a lot of examples of biopolymers in consumer products, but I’d be interested to know if any long-lasting bioplastics have made their way into construction. Oh, and next time you’re in the market for some plastic spoons, look for the ones made from corn.

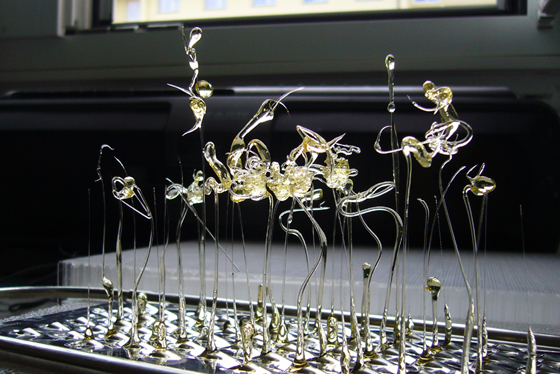

Freeform Plastic. Image courtesy architonic.com

Freeform Plastic. Image courtesy architonic.com

WU XING – WOOD

Biopolymers exhibit the characteristics attributed to wood: strength and flexibility. In this case, one of the primary benefits of using this material is the ease with which it is destroyed by natural processes: sunlight, water, etc. after it has served its purpose.

Cited:

Faircloth, Billie. “Plastic Paradigms in Architecture and Plastic.” Architecture and Plastic – acsa-arch.org. Accessed 01/27/10. URL.

Goldberry, Clare. “Plastics: The Bioresin Revolution.” Area Development.com June/July 2008. Accessed 01/26/10. URL.

Schmidt, Nora. “Moulded Nature.” Architonic.com. Accessed 01/26/10. URL.

Leave a Wordpress Comment: