Metafoam

Image courtesy wikimedia.org

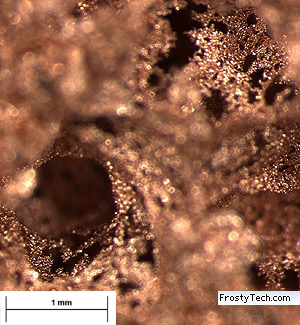

Any kind of metallic material that contains voids can be classified as metal foam. There are two distinct types: open-cell and closed-cell structures. The key difference between the two structures is that open-cell foams are permeable and will allow fluids to pass through the foam whereas closed-cell foams are impermeable (Metafoam). I found this handy description that further characterizes the different species of metal foam by John Banhart (Source: Metal Foam Info).

- cellular metal: space is divided into distinct cells. The boundaries of these cells are made of solid metal, the interiors are voids. Ideally, the individual cells are all separated from each other by metal but often this restriction is relaxed.

- porous metal: the metal contains a multitude of pores, i.e. closed, curved gas voids with a smooth surface.

- metal(lic) foam: foams are special cases of porous metals. A solid foam originates from a liquid foam in which gas bubbles are finely dispersed in a liquid.

- metal sponge: space is filled by pieces of metal that form a continuous network and co-exist with a network of empty space which is also interconnected.

Metal foams are great because of their massive surface area; they’re light because they consist mostly of air; they’re tough and can resist high temperatures, corrosion and humidity depending on what metals are foamed; they’re stiff and ductile and can absorb impact energy; they can be recycled. The downside is that metal foams are difficult to produce (by which I mean they are completely expensive and plagued by quality control issues).

Image courtesy frostytech.com

Metafoam manufactures open-cell metal foam for industrial electronics cooling and other applications. They’re working on producing copper foams to replace the current copper powder-based wick structures used in heat pipes and vapor chambers, developing products that “have up to 100 times more specific surface area (20,000 m²/m³ on average) than typical metallic foams. This represents more than 3 football fields of surface in a single cubic meter” (Metafoam). I love it when you can measure something in football fields.

What caught my eye about Metafoam was the extensive focus on “green” or “sustainable” manufacturing practices. We use a LOT of copper in the construction industry – especially in mechanical, electrical, and plumbing systems. The large surface area of a foam structure allows efficient heat transfer with much less material, and that saves energy. Any time you can use less of something you’re better off, but some of the statistics Metafoam provided in their product information surprised me. I don’t know if it’s true, but they assert that for every ton of copper they don’t have to use to manufacture a certain amount of metal foam, they save 22.0 cubic meters of fresh water. Using less material also tends to reduce SO2 emissions in the smelting stage of copper metal processing, and less sulfur releases into ground and surface water that during mining and tailing.

One of the reasons people steal copper from construction sites it that it’s so much easier to recycle copper than it is to mine it. The metal maintains 95% of its value from the primary metal from newly mined ore, so demounting and reselling someone’s rooster-shaped weathervane is a way to make some quick money.* Metafoam uses pure copper to make its foams, so it’s easily gathered up from scrap copper piles and sold for recycling purposes. Recycling copper conserves the resource and creates a sustainable market for the metal.

Image courtesy theweathervaneshop.com

WU XING:

Metal foam is going in the metal category – although I briefly contemplated putting it in fire because of all the air in it.

*I’m not advocating copper theft in any way whatsoever.

Cited:

Banhart, John. “What are Cellular Metals and Metal Foams?” Metal Foam Info. Accessed 02/19/10. URL.

Heon-Cheol Shin and Meilin Liu. “Copper Foam Structures with Highly Porous Nanostructured Walls.” Chemistry of Materials 11/07/04. Accessed 02/19/10. URL.

Leave a Wordpress Comment: