Bendywood

Image courtesy imagethief.com

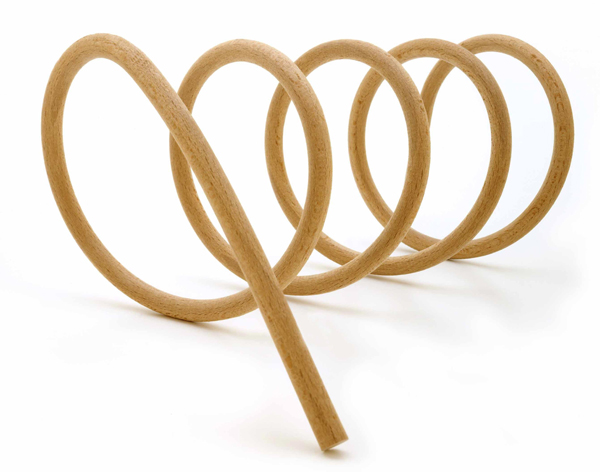

Here’s how it works: blanks of hardwood – beech, ash, oak, or maple – are steamed to soften the cell walls. (Woodworkers are now scratching their heads and wondering how this is different from any other operation in which you’d steam wood to bend it, but take it easy on your scalps my friends – this is a little bit different). The damp blanks are compressed along their length to around 20% of their former volume and allowed to dry. Since everything is pre-compressed, the tension that forms on the outside of a bend merely returns the cells to their former shape, and the wood doesn’t break. After the wood cools and dries, it stays flexible and pliable. Bendywood was developed for indoor uses such as furniture, handrails, or curved mouldings. It can’t be used outside EVER because the wood starts to expand when it gets wet.

Here’s a video of a person bending Bendywood:

Blanks come in a maximum size of 4-3/4’’ x 4-3/4’’ x 86-1/2’’ and can bend up to a radius of 10 times their thickness. Longer sections are supplied jointed, allowing for a radius 20 times the thickness. You can bend thin sections of Bendywood by hand, or for thicker sections you can use pulleys, clamps, or even ropes. Just use your imagination and have some fun with it (Source: Candidus Bruger).

Image courtesy www.via.fr

WU XING:

Bendywood is plastic – in the sense that it bends and can maintain its new shape. Also when we’re talking about wood, category assignment is a lot easier.

Cited:

Candidus Bruger. Bendywood online. Accessed 02/17/10. URL.

[…] is also Bendywood, a sort of permanently flexible, slightly dehydrated wood product. I’m not sure if similar […]

Leave a Wordpress Comment: